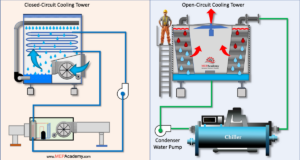

Closed Cooling Tower System

Descriptions

A closed cooling tower system operates by preventing the cooling fluid (such as water or a water-glycol mixture) from coming into direct contact with the outside air. Instead, the fluid flows through coils or a heat exchanger inside the tower, which is cooled by an external water flow or air stream.

How It Works:

The hot fluid enters the internal coils of the tower.

External water or air passes over the coils to cool them.

Heat transfers from the hot fluid through the coils to the surrounding water or air.

The cooled fluid is recirculated in the closed system.

Advantages:

Reduced Contamination: The internal fluid remains protected from external impurities.

Water Savings: Significantly reduces water consumption compared to open systems.

Ease of Maintenance: Minimizes corrosion and scaling inside pipes or equipment.

Versatility: Ideal for sensitive systems requiring high-quality water.

Disadvantages:

Higher Initial Cost: Requires more expensive closed heat exchanger systems.

Maintenance Needs: Coils and heat exchangers require regular cleaning for optimal efficiency.